The importance of bulk density measurement in the quality control of the pressing stage of ceramic tiles

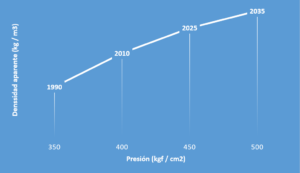

The porosity of the freshly pressed ceramic supports determines to a large extent the behaviour of the raw pieces during the process, and therefore their final properties as fired pieces. Controlling this porosity during pressing is essential due to the difficulty of measuring it directly, it is therefore measured bulk density as a physical quantity to monitor this stage. A the same physico-chemical properties of the atomised powder, the bulk density depends on the pressing pressure and the moisture content of the powder. The relationship between these parameters is represented in compaction diagrams, which are widely used to control the pressing operation.

Compaction diagram

Compaction diagram

The ideal pressing pressure, set and controlled by the technician or automatic systems, depends on the composition and moisture content of the atomised powder., which, from storage silos, is discharged into the mould cavities with a moisture content of 4-7% to be compacted at pressures between 350-500 Kg/cm2. The objective at this stage is to achieve maximum bulk density in the raw material for optimal sintering and compatible degassing during firing, resulting in products with lower water absorption and higher dimensional stability. The production control in the pressing stage tries to maintain a constant bulk density at the exit of the dryer throughout the batch, ensuring constant size in fired tiles. Moreover, it is also important to achieve a homogeneous distribution of the bulk density over the entire volume of the piece to avoid defects in the decoration phase and to ensure uniform shrinkage in the kiln, avoiding final mismatches.

X-ray density distribution map

X-ray density distribution map

In conclusion, the quality inspection of the pressed part must necessarily include a complete and precise measurement of the bulk densityin the entire ceramic tile. Fortunately, for several years now, thanks to various research and developments carried out at ITC-AICE, quality control through X-ray inspection has been introduced into the ceramic tile manufacturing process, a technique that is capable of providing agile and effective a complete map of density, thickness and load distribution throughout the volume of the part.